W88 ทางเข้าล่าสุดที่ใช้งานได้จริง

w88cuoc ทางเข้าสำรองยอดฮิตของ w88 สามารถใช้ได้ทุกเคลือข่ายอินเทอร์เน็ต

www.w88cuoc.com

อัปเดตล่าสุดเมื่อวันที่ 27/02/2024

w88goal เว็บพนันฟุตบอล เป็นผู้สนับสนุนอย่างเป็นทางการของสโมสรฟุตบอลเบิร์นลีย์

www.w88goal.com

อัปเดตล่าสุดเมื่อวันที่ 26/02/2024

w88io เว็บคาสิโนออนไลน์อันดับหนึ่งในเอเชีย อาทิเช่น กีฬา สล็อต คาสิโนสด บาคาร่า

www.w88io.com

อัปเดตล่าสุดเมื่อวันที่ 25/02/2024

แนะนำวิธีใช้งานเว็บ W88

เกี่ยวกับ W88

W88 เป็นเว็บพนันออนไลน์ที่มีการนำเสนอหลายรูปแบบของการเดิมพัน อาทิเช่น พนันกีฬา, เกมคาสิโนออนไลน์, โป๊กเกอร์, บาคาร่า, สล็อต เป็นต้น และเป็นหนึ่งในแพลตฟอร์มพนันออนไลน์ที่เป็นที่รู้จักและได้รับความนิยมในหลายประเทศทั่วโลกโดยเฉพาะในภูมิภาคเอเชีย ซึ่ง w88 นั้นได้เปิดบริษัทจดทะเบียนถูกต้องตามกฎหมายที่ประเทศฟิลิปปินส์ ไม่เพียงแค่เน้นในการให้บริการเกมพนันเท่านั้น w88 ยังได้มีการลงทุนในการตลาดและการเป็นสปอนเซอร์ ทางบริษัทได้ร่วมมือกับทีมกีฬาและองค์กรต่างๆ ทั่วโลก เพื่อเพิ่มความน่าเชื่อถือ เพิ่มการรับรู้แบรนด์และขยายฐานลูกค้า เป็นผู้สนับสนุนหลักของสโมสรฟุตบอลในทุกๆปี อาทิ ฟูลัม เลสเตอร์ซิตี้ ลิเวอร์พูล เบิร์นลีย์ เป็นต้น ทำให้ผู้ที่ทำการเดิมพันกับ w88 ได้รู้สึกอุ่นใจ

W88 มีการพัฒนาองค์กร และรูปการเสนอนำเกมการเดิมพันที่หลากหลาย ตั้งแต่การพนันกีฬาที่ครอบคลุมหลายประเภทกีฬา, การถ่ายทอดสดการแข่งขันกีฬา, ไปจนถึงเกมคาสิโนสดและสล็อตออนไลน์ นอกจากนี้ยังมีห้องโป๊กเกอร์ที่เปิดให้บริการตลอด 24 ชั่วโมง พร้อมทั้งมีการจัดโปรโมชั่นพิเศษมากมาย เพื่อให้ทั้งลูกค้าทั้งเก่าและใหม่สนุกกับการเดิมพันมากยิ่งขึ้น

ทางเข้า w88 เว็บตรงที่ได้รับความนิยมมากที่สุด

W88CLUB

โดเมนเว็บตรงของ w88 ที่เปิดให้ใช้งานสำหรับผู้ที่ใช้บริการในประเทศไทยตั้งแต่ปี 2013 และมีการรองรับภาษาไทย มีผู้ใช้งานและเข้าใช้บริการ w88 ผ่านช่องทาง w88club โดยมีการค้นหาผ่าน Search Engine โดยเฉลี่ยถึง 6,0000 ครั้งต่อเดือน

w88club ทางเข้า

W88OK

เป็นเว็บสำรองของ w88 ที่ซัพพอร์ตภาษาไทยใช้เพื่อเป็นช่องทางสำหรับใครที่ต้องการเดิมพันและไม่สามารถเข้าเว็บหลักได้ w88ok เป็นอีกหนึ่งทางเลือก ซึ่งเป็นเว็บตรงที่มีคนค้นหาถึง 4,400 ครั้งต่อเดือน

w88ok ทางเข้า

W88KUB

อีกตัวเลือกสำหรับใครที่เข้าเว็บไม่ได้ มีการจดทะเบียนขึ้นไปปี 2019 เพื่อใช้ในการรับรองผู้ที่ทำการเดิมพันกับ w88 มีผู้ใช้ที่นิยมใช้งานผ่าน w88kub มากกว่า 30,000 ยูสเซอร์ และมีอัตราการค้นหาต่อเดือนกว่า 3,000 ครั้งต่อเดือน

w88kub ทางเข้า

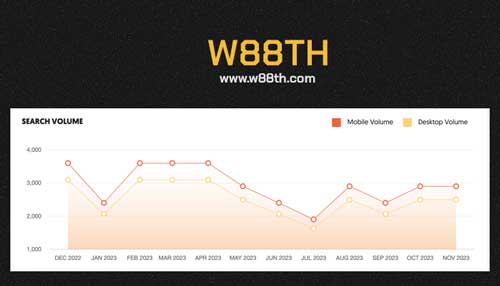

W88TH

เป็นเว็บเก่าแก่เปิดมานานกว่า 10 ปี เริ่มต้นจดทะเบียนราวๆปี 2014 ในอดีตเคยเป็นเว็บลูกค้า w88 ใช้งานมากที่สุดในไทย โดยในปัจจุบันก็ยังมีคนใช้งาน w88th อยู่เรื่อยๆ โดยอัตราการค้นหาประมาณ 3,500 ครั้งต่อเดือน และมียูสเซอร์ใช้งานผ่านหน้าเว็บนี้กว่า 15,000 คน

w88th ทางเข้า

W88BKK

w88bkk หรือ W88 Bangkok ทำขึ้นมาสำหรับผู้ที่เล่นสกุลเงิน THB โดยเฉพาะ เป็นเว็บที่พึ่งเปิดใหม่เมื่อปี 2023 และมาแรงที่สุดในขณะนี้ในแง่ของอัตราการเติบโตของผู้ใช้งาน โดยปัจจุบันผู้ที่ทำการค้นหาด้วยคำว่า w88bkk สูงถึง 1,000 คนต่อเดือน สำหรับเว็บทางเข้าใหม่เป็นตัวเลือกที่ผู้ใช้งานนิยมมากที่สุด

w88bkk ทางเข้า

W888

สำหรับ w888 นั้นไม่ใช่เว็บสำรอง แต่เป็นเว็บทางเข้าที่คนนิยมใช้กันทำให้เวลาจะเดิมพันกับ w88 มักจะทำการเข้าผ่านทางเว็บ w888 เพราะมีบางครั้งที่เว็บไซต์ทางสำรองบางเว็บไม่สามารถใช้งานได้ตามปกติ โดยมีคนใช้งานเดิมพันผ่านเว็บ w888 สูงถึง 5,000 คนต่อเดือน

w888 ทางเข้า

WW88

ww88 ไม่ใช่เว็บทางเข้าและเว็บสำรองของ w88 แต่ว่าชื่อที่ผู้ใช้งานบางกลุ่มเรียกเพราะใน logo ของ w88 official นั้นมีตัว W ตัวใหญ่สีเหลืองใน logo ที่เด่นเป็นพิเศษ ซึ่งทำให้บางครั้งคนเข้าใจผิดว่า w88 คือ ww88 ทำให้มีการค้นหา w88.com ในชื่อของแบรนด์นี้สูงถึง 6,500 ครั้งต่อเดือนเลยทีเดียว

ww88 ทางเข้าความนิยมของ W88

สำหรับเว็บไซต์ w88 นั้นจัดได้ว่าเป็นเว็บพนันออนไลน์ที่ได้รับการยอมรับเป็นวงกว้าง มีผู้ใช้งานจริงกว่า 5,000,000 ยูสเซอร์ทั่วโลก มียอดคนค้นหามากกว่า 10 ล้านครั้งต่อเดือน เฉพาะในประเทศไทยก็มีการค้นหาสูงถึง 250,000 ครั้งต่อเดือนแล้ว ดังนั้นสำหรับใครที่กำลังมองหาเว็บพนันออนไลน์ที่น่าเชื่อถือจ่ายจริง www.w88.com จึงเป็นอีกหนึ่งตัวเลือกที่เหมาะสมเป็นอย่างยิ่ง

ทำไม w88 จึงมีหลายโดเมน

หลายคนคงสังเกตแล้วว่า w88 นั้นมีหลายโดเมนและหลายเว็บไซต์ แต่ละเว็บนั้นมีความแตกต่างกันอย่างไร วันนี้เราจะมาไขข้อข้องใจเรื่องนี้กัน

ความจริงแล้วสำหรับสมาชิกทุกท่านที่ทำการสมัครมาร่วมเดิมพันกับทาง w88 ไม่ว่าจะผ่านช่องทางเว็บไซต์ใดของ w88 ก็ตามอาทิเช่น w88kub, w88th, w88ok, w88club ท่านสามารถใช้ user เดียวกันนี้เดิมพันได้กับทุกเว็บ เพราะจริงๆแล้วทุกเว็บคือเว็บเดียวกัน ใช้ฐานข้อมูลเดียวกัน แต่เหตุผลที่มีหลายเว็บมาจาก 2 ปัจจัยดังนี้

- ภาษา ในประเทศไทยซึ่งใช้ภาษาไทยเป็นหลัก จึงมีเว็บโดเมนย่อยมาเพื่อรองรับภาษาไทยโดยเฉพาะ

- โดนบล็อก บางประเทศไม่อนุญาตให้มีการเล่นพนันออนไลน์ จึงทำให้มีการบล็อกเว็บหลัก ทำให้ต้องมีสำรองเพื่ออำนวยความสะดวกให้กันผู้ใช้บริการในพื้นที่นั้นๆ

ทำไมถึงต้องมีเว็บทางเข้า

- ช่วยอำนวยความสะดวก เพื่ออัปเดตเว็บตรงที่สามารถใช้งานได้ล่าสุด กรณีเว็บที่เราใช้งานอยู่เป็นประจำโดน ICT บล็อก

- เพื่อความปลอดภัยของผู้ใช้งาน ป้องกันเว็บปลอมที่ทำการหลอกลวงและแอบอ้างว่าเป็น w88 ซึ่งอาจมีการทำหน้า UX/UI ที่คล้ายกับของ w88 เพื่อหลอกเอา User/Password ของเรา

โปรโมชั่น

W88 คาสิโนสด

ในหมวดของคาสิโนสด จะเป็นการถ่ายทอดสดการเดิมพันเพื่อให้ได้บรรยากาศเหมือนไปเดิมพันที่คาสิโนด้วยตัวเอง โดยมีประเภทและหมวดหมู่ให้เลือกเดิมพันที่หลากหลาย อาทิ บาคาร่า, แบล็กแจ็ก, ไพ่ 3 ใบ, ไฮโล, รูเล็ต เป็นต้น

กีฬา

ในส่วนของการเดิมพันกีฬา ก็จะมีหลากประเภทกีฬาให้เดิมพันเช่นกัน อาทิ ฟุตบอล, บาสเกตบอล, วอลเลย์บอล, เทนนิส, มวย, e-sports เป็นต้น สามารถเลือกแทงได้ทั้งแบบอัตราต่อรองปกติ และหากเป็นแบบ Advance ขึ้นหน่อยก็จะเป็น สูงต่ำ คู่คี่ เตะมุม ฟาวล์ เขี่ย เป็นต้น นอกจากนี้จะมีในหมวดของบอลสด ซึ่งอัตราต่อรองก็จะไหลไปตามเวลาและผลการแข่งขัน ณ ขณะนั้น ผลตอบแทนอัตราการจ่ายก็จะปรับตามช่วงเวลานั้นๆด้วยเช่นกัน

สล็อต

w88 มีเกมสล็อตมากมายหลายค่ายให้ได้เลือกเดิมพัน สล็อตเว็บตรงแตกง่ายจากค่ายเกมชั้นนำทั่วโลก อาทิเช่น PG, Gameplay Interactive, Evolution, Microgaming, Play’N Go, QTech, PlayTech, BNG, Genesis, YGGDRASIL เป็นต้น นอกจากนี้ยังสามารถเติมเงินเดิมพันสล็อตผ่าน True wallet ได้ง่ายๆไม่จำเป็นต้องโอนเงินผ่านธนาคาร

หวย

W88 ได้มีการส่งเสริมและพัฒนาการพนันหลากหลายประเภท เพื่อเพิ่มความหลากหลายไม่จำเจให้กับผู้ใช้งาน ล่าสุดมีแคมเปญหวย เช่น หวยไทย, หวยลาว, หวยฮานอย, หวย API เพิ่มเข้ามาให้ผู้เล่นได้ร่วมสนุก

P2P

ในโหมดของ Peer To Peer เป็นโหมดที่ User ทำการเดิมพันกันเอง ทางระบบคิดแค่ค่าใช้บริการในการสร้างห้อง เหมาะสำหรับผู้ที่ต้องการความแปลกใหม่ คล้ายกับตั้งวงเดิมพันกันเองจริงๆ อาทิเช่น Poker, เก้าเก, ป๊อกเด้ง, ไพ่เซียนเวียดนาม, ไพ่สลาฟเวียดนาม เป็นต้น

รีวิวต่างๆที่น่าสนใจ

W88

การรักษาความปลอดภัยของข้อมูล

การปกป้องข้อมูลส่วนบุคคลและทางการเงินของลูกค้าเป็นสิ่งสำคัญที่ W88 ให้ความสำคัญ เว็บไซต์ใช้เทคโนโลยีการเข้ารหัสข้อมูลล่าสุดเพื่อให้แน่ใจว่าข้อมูลของผู้ใช้ถูกเก็บรักษาอย่างปลอดภัย และทางบริษัทไม่มีนโยบายเปิดเผยข้อมูลของลูกค้าไม่ว่ากรณีใดๆทั้งสิ้น

รีวิวและความคิดเห็นจากผู้ใช้

รีวิวและความคิดเห็นจากผู้ใช้จริงเป็นอีกหนึ่งวิธีที่ช่วยในการประเมินความน่าเชื่อถือ มีความคิดเห็นที่หลากหลายจากผู้ใช้ ซึ่งส่วนใหญ่มีทัศนคติที่ดีต่อบริการและประสบการณ์การเล่น มีความประทับใจที่จะเดิมพันต่อในระยะยาว

การสนับสนุนลูกค้า

ทางเว็บมีการบริการสนับสนุนลูกค้าที่มีประสิทธิภาพ และการตอบกลับเพื่อแก้ไขปัญหาที่รวดเร็วเป็นส่วนสำคัญ W88 มีทีมสนับสนุนที่พร้อมให้คำปรึกษาและแก้ไขปัญหาให้กับผู้ใช้ตลอด 24 ชั่วโมง

ความรับผิดชอบในการเล่น

W88 ยังส่งเสริมการเล่นอย่างมีความรับผิดชอบ โดยมีเครื่องมือและนโยบายที่ช่วยให้ผู้เล่นสามารถควบคุมการเล่นและหลีกเลี่ยงปัญหาที่เกิดจากการพนัน หากมีปัญหาเนื่องจากทางระบบของ w88 ทางทีมงานก็พร้อมที่จะรับผิดชอบความเสียหายในส่วนที่เกิดจากทางระบบนั้นๆทำงานผิดพลาด

ใบอนุญาตและการกำกับดูแล

หนึ่งในปัจจัยหลักที่ช่วยในการประเมินความน่าเชื่อถือของ W88 คือการมีใบอนุญาตการดำเนินธุรกิจ W88 ได้รับใบอนุญาตจากหน่วยงานที่มีชื่อเสียงในอุตสาหกรรมการพนัน ซึ่งรับรองว่ามีการดำเนินงานตามมาตรฐานและกฎระเบียบที่กำหนด

สามารถเติมเงินได้หลายช่องทาง

มีระบบจัดการการเติมเงินหลากหลายรูปแบบ เพื่อรองรับความสะดวกของผู้ใช้งาน เพราะหลายคนมากหน้าหลายตา อาจจะสะดวกเติมเงินในช่องทางที่ไม่เหมือนกัน ตัวอย่างเช่น LinePlay, True wellet, QR Code เป็นต้น

เหรียญดิจิทัล Crypto ไม่ตกเทรนด์

ปัจจุบันเหรียญดิจิทัลกำลังได้รับความนิยมสูงมาก ทางทีมงานแลเห็นถึงความสำคัญในเรื่องนี้จึงได้มีการจัดการระบบบัญชี Crypto ขึ้น ท่านสามารถฝากเงินโดยใช้เหรียญดิจิทัลผ่านช่องทางบัญชี Crypto เพื่อมาทำการเดิมพันได้

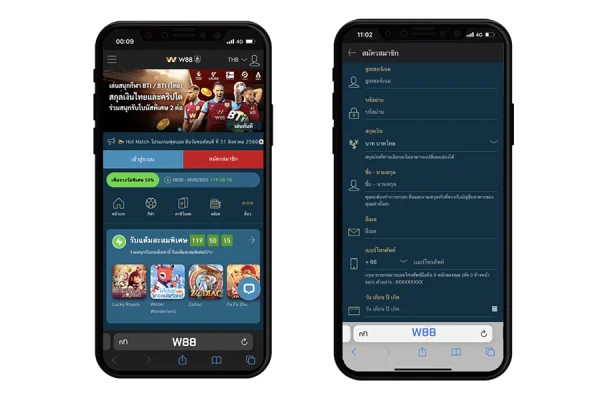

W88 Mobile

ในยุคสมาร์ทโฟนที่ก้าวไกล เว็บไซต์บนมือถือไม่เพียงแต่เป็นเครื่องมือสำคัญในการเข้าถึงข้อมูลและบริการต่างๆ แต่ยังเป็นส่วนหนึ่งของการใช้ชีวิตประจำวัน การพัฒนาเว็บไซต์ให้เข้ากับอุปกรณ์มือถือเป็นเรื่องสำคัญสำหรับธุรกิจและองค์กรในทุกขนาด จึงทำให้ w88 แลเห็นถึงความสำคัญของเว็บไซต์มือถือในยุคดิจิทัล

เมื่อไม่กี่ปีที่ผ่านมา เว็บไซต์ W88 ถูกออกแบบมาเพื่อการดูจากเดสก์ท็อปเป็นหลัก อย่างไรก็ตาม ด้วยการเพิ่มขึ้นของการใช้สมาร์ทโฟน จึงความต้องการสำหรับเว็บไซต์ที่เหมาะสมกับมือถือได้เพิ่มขึ้นอย่างมาก W88 ได้มีการปรับให้เว็บไซต์เข้ากับหน้าจอขนาดเล็กและการทำงานที่สะดวกบนอุปกรณ์พกพา และเพิ่มปัจจัยหลักในการออกแบบเว็บไซต์สมัยใหม่ซึ่งก็คือ W88 Mobile นั่นเอง

จุดเด่นของ W88 Mobile

- การเข้าถึงได้ง่ายและรวดเร็ว ผู้ใช้สามารถเข้าถึงเว็บไซต์ได้ทุกที่ทุกเวลาผ่านสมาร์ทโฟน, ทำให้ข้อมูลและบริการต่างๆ อยู่ในมือผู้ใช้

- ประสบการณ์ผู้ใช้ที่ดีกว่า เว็บไซต์ที่ถูกออกแบบมาเพื่อมือถือมีการโหลดที่เร็วขึ้นและมีการแสดงผลที่เหมาะสมกับหน้าจอขนาดเล็ก, สร้างประสบการณ์ที่ดีกว่าสำหรับผู้ใช้

การออกแบบเว็บไซต์ W88 มือถือ

การออกแบบเว็บไซต์มือถือจำเป็นต้องคำนึงถึงปัจจัยหลายอย่าง, เช่น ความเร็วในการโหลด, การใช้งานที่ง่ายดาย, และการแสดงผลที่เหมาะสม. การใช้ Responsive Design ซึ่งเป็นการออกแบบที่ทำให้เว็บไซต์สามารถปรับตัวเข้ากับหน้าจอขนาดต่างๆ ได้อย่างลงตัว, เป็นวิธีที่ได้รับความนิยม

แอปพลิเคชันสำหรับมือถือ W88 LITE

ในโลกปัจจุบันความสะดวกสบายในการพกพามือถือ การใช้งานเว็บไซต์และซอฟต์แวร์ Mobile Application มีแนวโน้มที่สูงขึ้นอย่างก้าวกระโดด ทาง W88 จึงมีการออกแบบพัฒานาแอปพลิเคชันบนมือถือขึ้น โดยแอปพลิเคชันนี้มีชื่อว่า W88 Lite เพื่อให้ตอบโจทย์ผู้ใช้งานบนมือถือมากยิ่งขึ้น ไม่ว่าจะด้านความเร็ว หรือ UX UI ในการใช้งาน มีทุกประเภทการเดิมพันที่เหมือนกับคุณเล่นบนหน้าเว็บ แต่ปรับให้เหมาะสำหรับการเล่นบนมือถือ คุณสามารถดาวน์โหลดหรืออ่านวิธีการทำงานได้ที่

คู่มือการใช้งาน W88 LITEบทความที่น่าสนใจ

วิธีเลือกรับโปรโมชั่น | อันตรายซ่อนเร้นที่หลายคนมองข้าม

สอนวิธีเลือกรับโปรโมชั่นเว็บพนันออนไลน์ เลือกโปรโมชั่นอย่างไรให้ถูกวิธี มือใหม่ควรระวัง เลือกผิดชีวิตเปลี่ยน นอกจากจะไม่ไได้กำไรยังขาดทุน

Apr

รีวิว Starburst เกมสล็อตจากค่าย EVOLUTION

รีวิว Starburst เกมสล็อตแตกง่ายจากค่าย EVOLUTION ของเว็บ w88 เกมสล็อต 5 วงล้อ 3 แถว อัตราแจกเงินรางวัลอยู่ที่ผลตอบแทนตามระบบอยู่ที่ 96%

Jan

คาสิโนสด W88 รับโบนัสเครดิตฟรี 288 บาท ทุกวัน

โปรโมชั่นสุดพิเศษ เดิมพันคาสิโนสดกับ w88 ในหมวด w คลับ รับโบนัสเครดิตฟรีถึง 288 บาททุกวัน มาก่อนรับก่อน สิทธิ์มีจำนวนจำกัด

Jan

การวิวัฒนาการของสล็อต ตู้เกมมหัศจรรย์สู่เกมสล็อตออนไลน์

ต้นกำเนิดของสล็อต การวิวัฒนาการจากตู้เกมมหัศจรรย์ จนมาสู่เกมสล็อตออนไลน์ พร้อมกับสิ่งที่น่าสนใจเกี่ยวกับการทำงานของตู้สล็อต

Jan

เก้าเกออนไลน์ รีวิว โหมด P2P จาก W88 ผู้เล่นเจอกันเอง

รีวิวไพ่เก้าเกออนไลน์แบบ P2P ของเว็บ w88.com เป็นการจับคู่เดิมพันระหว่างผู้กับผู้เล่น สามารถเลือกวงตามประเภทเดิมพันขั้นต่ำได้

Jan

M88Asia ทางเข้า M88 เว็บตรง 2024 โบนัสเติมเงิน 100%

M88Asia ทางเข้า M88 เว็บตรง 2024 สมัครสมาชิกรับโปรโมชั่นพิเศษ โบนัสเติมเงิน 100% มีเกมพนันมากมายอาทิเช่น กีฬา สล็อต บาคาร่า เป็นต้น

Jan

เว็บเพื่อนบ้านที่คล้ากัน

M88 หรือ M88Asia เว็บพนันออนไลน์จากเอเชีย เป็นที่นิยมเดิมพันไปทั่วโลกและเป็นผู้สนับสนุนทีม AC Milan และลีกลาลีกาสเปน ให้บริการเกมพนันหลากหลายเช่น กีฬา สล็อต บาคาร่า E-Sports

อ่านเพิ่มเติมเกี่ยวกับ M88 Asia